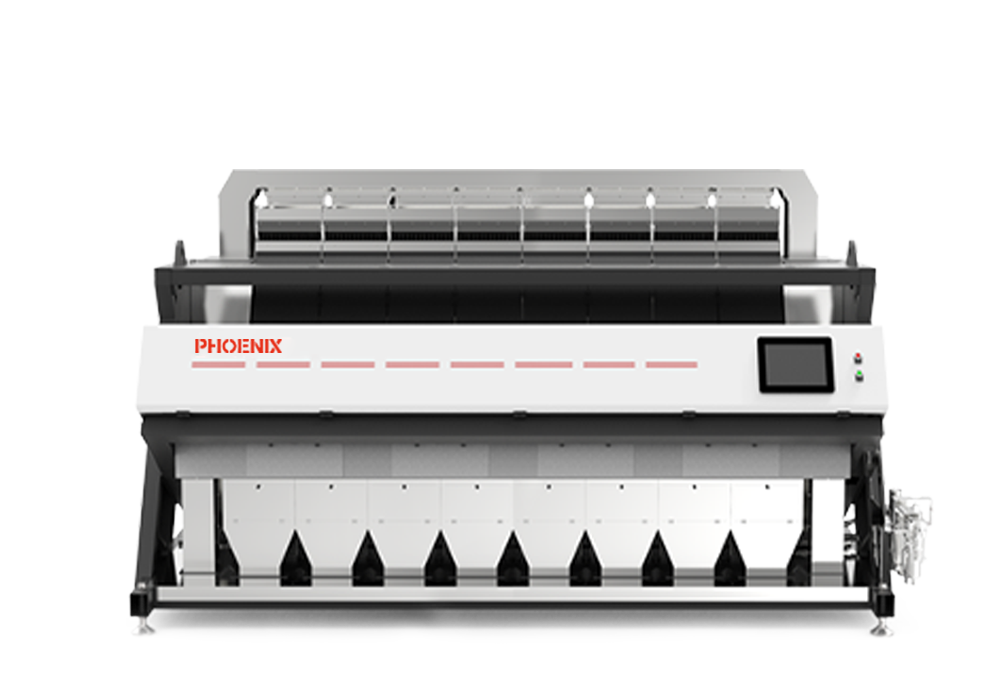

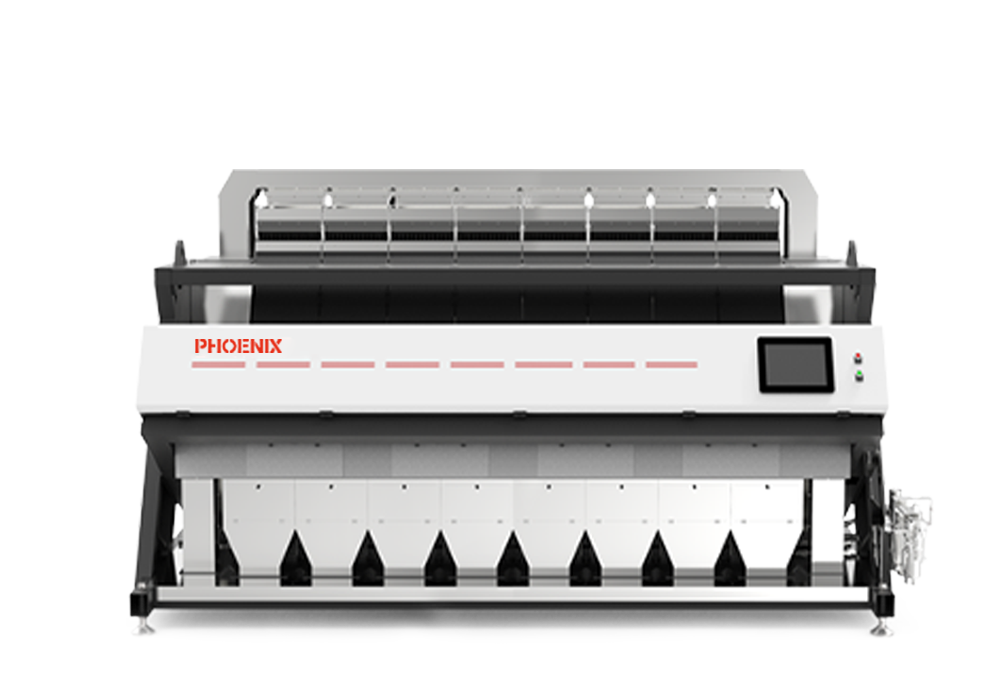

Preparation work for plastic color selection machine before and after startup

(1) Before starting, check if the air inlet of the fan is blocked and promptly eliminate the blockage.

(2) Check if the air pressure, ash cleaning device, spray valve, and fuse of the color sorter are normal and the color separation effect is good.

(3) During the operation of the color sorter, special attention should be paid not to damage the surface when cleaning components such as lenses, to avoid affecting the color separation effect. Timely clean up the material leakage of the color selection machine, and after cleaning, deliver the scattered materials to the plastic warehouse.

(4) During the operation of the color sorter, check the color separation status every half an hour and adjust the operating parameters of the color sorter in a timely manner if any problems are found.

-

Why do we use a color sorter for ore?Dec,22,2023

Why do we use a color sorter for ore?Dec,22,2023 -

Preparation work for plastic color selection machine before and after startupDec,25,2023

Preparation work for plastic color selection machine before and after startupDec,25,2023 -

What are the factors that affect the effectiveness of ore color sorting machinesDec,21,2023

What are the factors that affect the effectiveness of ore color sorting machinesDec,21,2023 -

Can the rice color selection machine select brown rice?Dec,21,2023

Can the rice color selection machine select brown rice?Dec,21,2023 -

The rice selected by the color selection machine is the reliable riceDec,20,2023

The rice selected by the color selection machine is the reliable riceDec,20,2023

Links

Links